400kN anti-slip coefficient testing instrument

Classification:

Key words:

Product Details

400kN anti-slip coefficient testing instrument HY-24L

1. Product Introduction:

- The LLG-24HY anti-slip coefficient testing instrument is mainly suitable for testing the anti-slip coefficient of friction surfaces in high-strength bolt connections of grade 10.9 and 8.8, as well as in high-strength large hexagon head bolt connections and torsional shear type high-strength bolt connections (a special wrench for torsional shear needs to be ordered separately), testing, and research.

- High-strength bolt connection: A general term for high-strength bolts and their matching nuts and washers;

- Anti-slip coefficient: The ratio of the external force that causes the friction surface of the connection to slide in high-strength bolt connections to the sum of the pre-tension force of the high-strength bolt perpendicular to the friction surface;Force与垂直于摩擦面的高强度螺栓预拉力之和的比值;

- LLG-TEST LCD microcomputer force measuring instrument,It has four physical channels,6groups in total24logical channels.

- Parameter backup and recovery functions, peak hold function, automatic calibration function.

- Specifications for high-strength large hexagon head bolts:M16, M20, M22, M24, M27, M30.

- Specifications for torsional shear type high-strength bolts:M16, M20, M22, M24.

- To facilitate users to connect with computers, the LLG358 interface is set up (needs to be ordered separately), which can transmit data to the computer for further processing and printing of test reports.

- This device is easy to operate, convenient to carry if sent for calibration by measurement departments, and extremely convenient for future equipment upgrades and maintenance. This device is currently a low-investment, high-return high-strength bolt testing instrument widely favored by high-strength bolt manufacturing enterprises, engineering quality testing institutions, steel structure construction units, engineering supervision agencies, high-speed railways, bridge electricity, and research institutions such as colleges and universities.

- Product Technical Parameters:

|

Item/Category |

Indication Mark |

|

Maximum Test Force |

400kN |

|

Measurement Range |

20kN∽400kN |

|

Resolution |

±0.05kN |

|

Indication Error |

±1.0% |

|

Display Method |

LCD touch display |

3. Parameters and Configuration

|

LLG-24HY anti-slip coefficient testing instrument |

Remarks |

||

| 1 | Sensor Measuring Range | 20kN~400kN | |

| 2 | Sensor Resolution | 0.05kN | |

| 3 | Relative Error of Resolution | ≤±1.0% | |

| 4 | Force Measuring Instrument | LLG-TEST touch screen microcomputer |

Independently developed |

| 5 | 120kN through-hole sensor | 4 pieces/M16 | Ningbo Zhenhai |

| 6 | 180kN through-hole sensor | 4 pieces/M20 | Ningbo Zhenhai |

| 7 | 220kN through-hole sensor | 4 pieces/M22 | Ningbo Zhenhai |

| 8 | 260kN through-hole sensor | 4 pieces/M24 | Ningbo Zhenhai |

| 9 | 330kN through-hole sensor | 4 pieces/M27 | Ningbo Zhenhai |

| 10 | 400kN through-hole sensor | 4 pieces/M30 | Ningbo Zhenhai |

| 11 | Adjustable Wrench |

375 mm |

Taiwan Dongliang |

| 12 | Socket 27, 34, 36, 41, 46, 50 | 13 | Taiwan Dongliang |

| Socket Wrench | 1 piece | Dongliang | 14 |

| Sliding Head | 滑头 | 1 piece | 14 |

| 15 | Custom safe | 1 set |

Homemade |

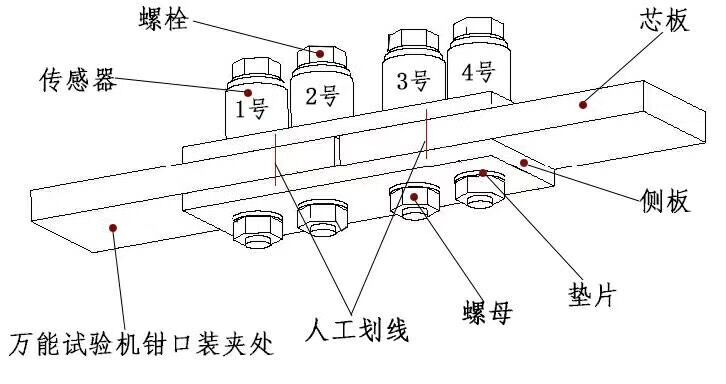

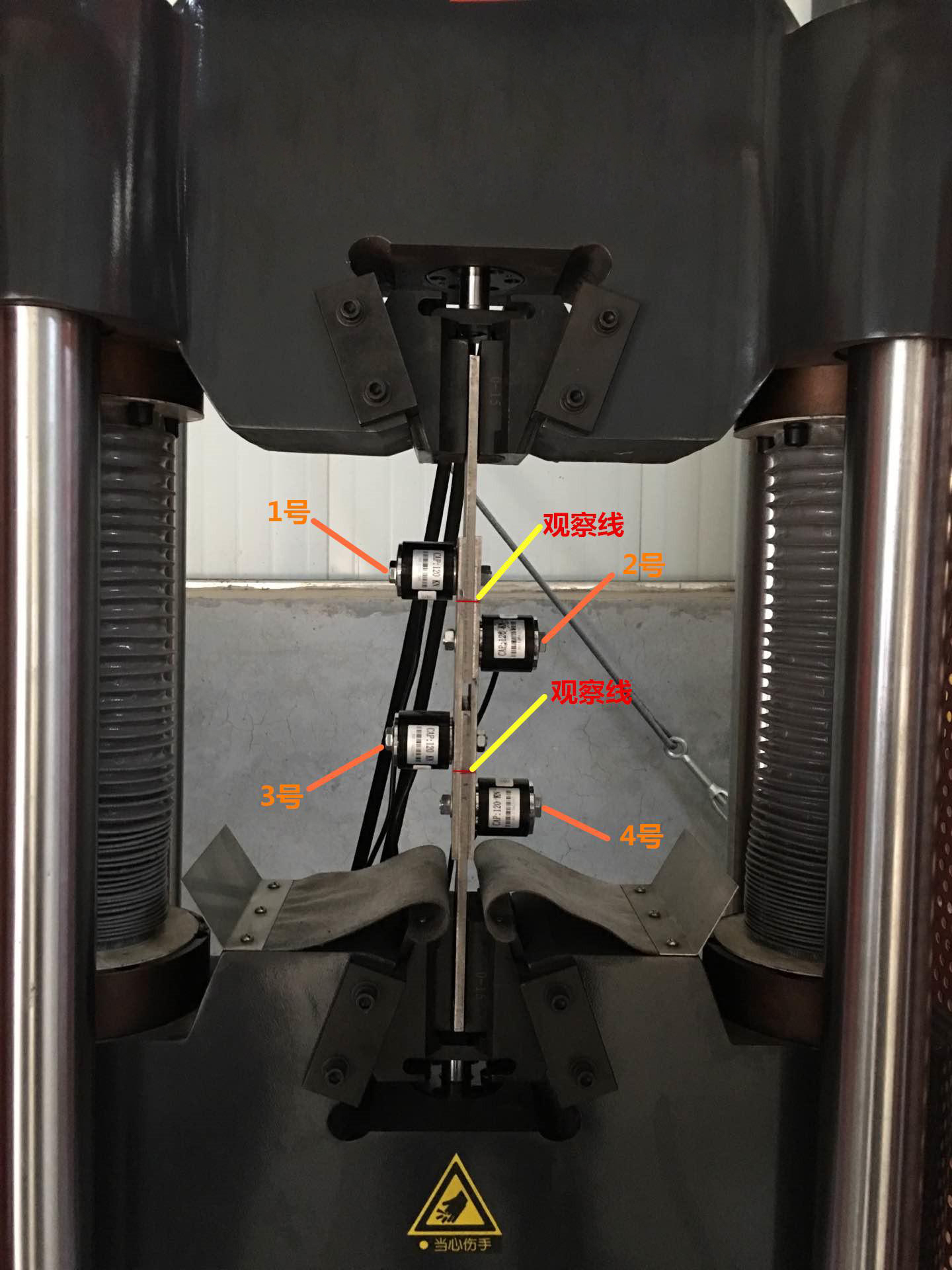

4. Product physical and test illustrations

|

|

| (Figure 5.1 llG-24HY overall view) | (Figure 5.2 Test example illustration) |

|

|

| (Figure 5.3 Slide plate installation position diagram) | (Figure 5.4 Slide control instrument) |

|

|

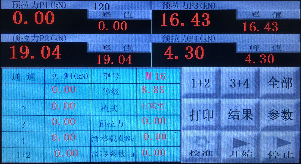

| (Test main interface) | (Test status interface) |

6. User preparation conditions

-

- It is required to clarify the test method standards that the test refers to as much as possible.

- Provide samples to complete the test on this machine for product testing and factory inspection.

- Responsible for receiving, storing, and positioning the product.

- Contact the local metrology department for equipment measurement.

- Space and power supply required for equipment installation.

Related Products

Product inquiry

If you are interested in the product, please fill in the information and leave us a message, we will get in touch with you as soon as possible.

online message

Bottom link

Contact Us

Company Address:No.88, Ke Yun Road, Licheng District, Jinan City, Shandong Province

Sales Hotline: 008613204662621

Enterprise E-mail:dawn@tianchentest.com