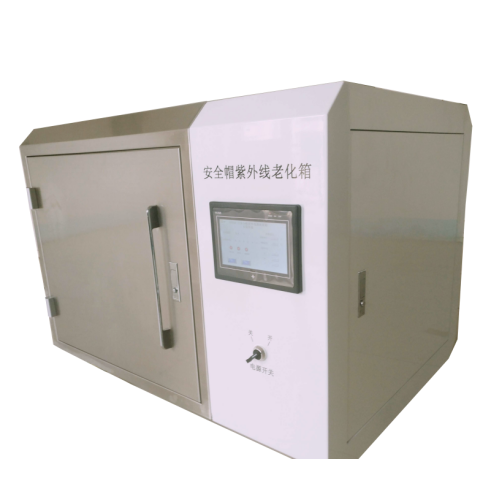

TC705B-II Safety Helmet UV Aging Box

Classification:

Key words:

Product Details

TC705B-II Safety Helmet UV Aging Box

1. Main Purpose

Designed according to the latest national standards GB/T2812 - Safety Helmet Testing Methods and GB 2811 - Safety Helmets, mainly used for the UV pre-treatment test of safety helmets.

1. Main Structure: The test box is made of all stainless steel, effectively protecting the safety of the test and extending its service life. Internal components are made of metal or PTFE to ensure that the aging from the test does not affect the test results. The oversized test box ensures that 14 safety helmets can be tested at once.

2. Temperature Measurement System: Uses high-precision PT100 sensors and PID temperature controllers to test and monitor the test temperature in real-time.

3. Protection System: Built-in over-temperature protection system, automatically cuts off power when the temperature exceeds the preset value; power cut-off protection system when the test door is opened.

, when the test door is opened, the power is automatically cut off. Equipped with a light sensor to monitor the operation of the xenon lamp in real-time, with automatic alarm and recording of operating time when the lamp goes out.

4. Light Source System: Uses a 450W short pulse high-pressure xenon lamp, specifically configured with a matching power trigger to ensure the stability of the light source.

5. Control System: Uses a PLC control system, touch screen human-machine interface (HMI), and color LCD screen.

6. Cooling System: Uses a 'downward air intake, upward air exhaust' air-cooled cooling system. A dedicated turbine fan ensures that external air flows uniformly over the surface of the xenon lamp and inside the test box, ensuring that the temperature does not exceed the standard requirement of 60°C, extending the service life of internal components.

3. Technical Indicators

1. UV Irradiation Source: Short pulse high-pressure xenon lamp, 220V, 450W.

2. Cooling Method: Air-cooled, ensuring that the test temperature meets standard requirements.

3. Timing Range: 0-999 hours. Displays test time. Alarm prompt when test time is up.

4. Number of Safety Helmets for Pre-treatment: 1-14 helmets.

5. Working Power Supply: AC220V, 50Hz, 800W.

6. Distance from Safety Helmet to Lamp: 150mm, with a dedicated testing ruler.

4. Applicable Standards

GB2811, GB/T2812

Related Products

Product inquiry

If you are interested in the product, please fill in the information and leave us a message, we will get in touch with you as soon as possible.

online message

Bottom link

Contact Us

Company Address:No.88, Ke Yun Road, Licheng District, Jinan City, Shandong Province

Sales Hotline: 008613204662621

Enterprise E-mail:dawn@tianchentest.com