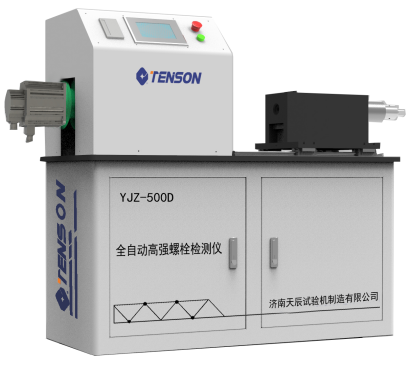

Fully automatic high-strength bolt testing instrument YJZ-500D

Classification:

Key words:

Product Details

400kN Anti-Slip Coefficient Testing Instrument HY-24L

1. Product Introduction:

- The LLG-24HY anti-slip coefficient testing instrument is mainly suitable for testing the anti-slip coefficient of friction surfaces in high-strength bolt connections of grade 10.9 and 8.8, as well as for testing the anti-slip coefficient of friction surfaces in torsional shear type high-strength bolt connections (a special wrench for torsional shear needs to be ordered separately), testing, and research.

- High-strength bolt connection: A general term for high-strength bolts and their matching nuts and washers;

- Anti-slip coefficient: The ratio of the external force that causes the friction surface of the connection to slide to the sum of the pre-tension of the high-strength bolt perpendicular to the friction surface in high-strength bolt connections;

- LLG-TEST LCD microcomputer force measuring instrument, with four physical channels and a total of 24 logical channels in 6 groups.

- Parameter backup and recovery function, peak hold function, automatic calibration function.

- Specifications for high-strength large hexagon head bolts: M16, M20, M22, M24, M27, M30.

- Specifications for torsional shear type high-strength bolts: M16, M20, M22, M24.

- To facilitate users in connecting to a computer, the LLG358 interface is set up (needs to be ordered separately), allowing data to be transmitted to a computer for further processing and printing of test reports.

- This device is easy to operate, convenient to carry if sent for calibration by measurement departments, and extremely convenient for future equipment upgrades and maintenance. This device is currently a low-investment, high-return high-strength bolt testing instrument widely popular among high-strength bolt manufacturing enterprises, engineering quality testing institutions, steel structure construction units, engineering supervision agencies, high-speed railways, bridge electricity, and research institutions such as colleges and universities in China.

- Product Technical Parameters:

|

Item/Category |

Indicator |

|

Maximum Test Force |

400kN |

|

Measurement Range |

20kN∽400kN |

|

Resolution |

±0.05kN |

|

Display Error |

±1.0% |

|

Display Method |

LCD Touch Display |

3. Parameters and Configuration

|

LLG-24HY Anti-Slip Coefficient Testing Instrument |

Remarks |

||

| 1 | Sensor Measurement Range | 20kN~400kN | |

| 2 | Sensor Resolution | 0.05kN | |

| 3 | Relative Error of Resolution | ≤±1.0% | |

| 4 | Force Measuring Instrument | LLG-TEST Touch Screen Microcomputer |

Independently Developed |

| 5 | 120kN Through-Core Sensor | 4 pieces/M16 | Ningbo Zhenhai |

| 6 | 180kN Through-Core Sensor | 4 pieces/M20 | Ningbo Zhenhai |

| 7 | 220kN Through-Core Sensor | 4 pieces/M22 | Ningbo Zhenhai |

| 8 | 260kN Through-Core Sensor | 4 pieces/M24 | Ningbo Zhenhai |

| 9 | 330kN Through-Core Sensor | 4 pieces/M27 | Ningbo Zhenhai |

| 10 | 400kN Through-Core Sensor | 4 pieces/M30 | Ningbo Zhenhai |

| 11 | Adjustable Wrench |

375mm |

Taiwan Dongliang |

| 12 | Socket | 27, 34, 36, 41, 46, 50 | Taiwan Dongliang |

| 13 | Socket Wrench | 1 piece | Dongliang |

| 14 | Sliding Head | 1 piece | Dongliang |

| 15 | Custom Safe | 1 set |

Self-made |

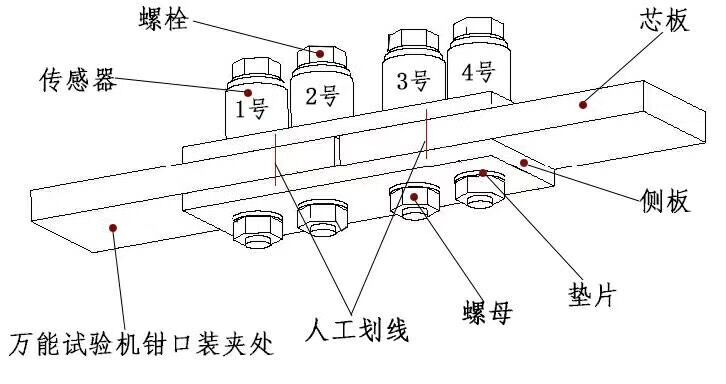

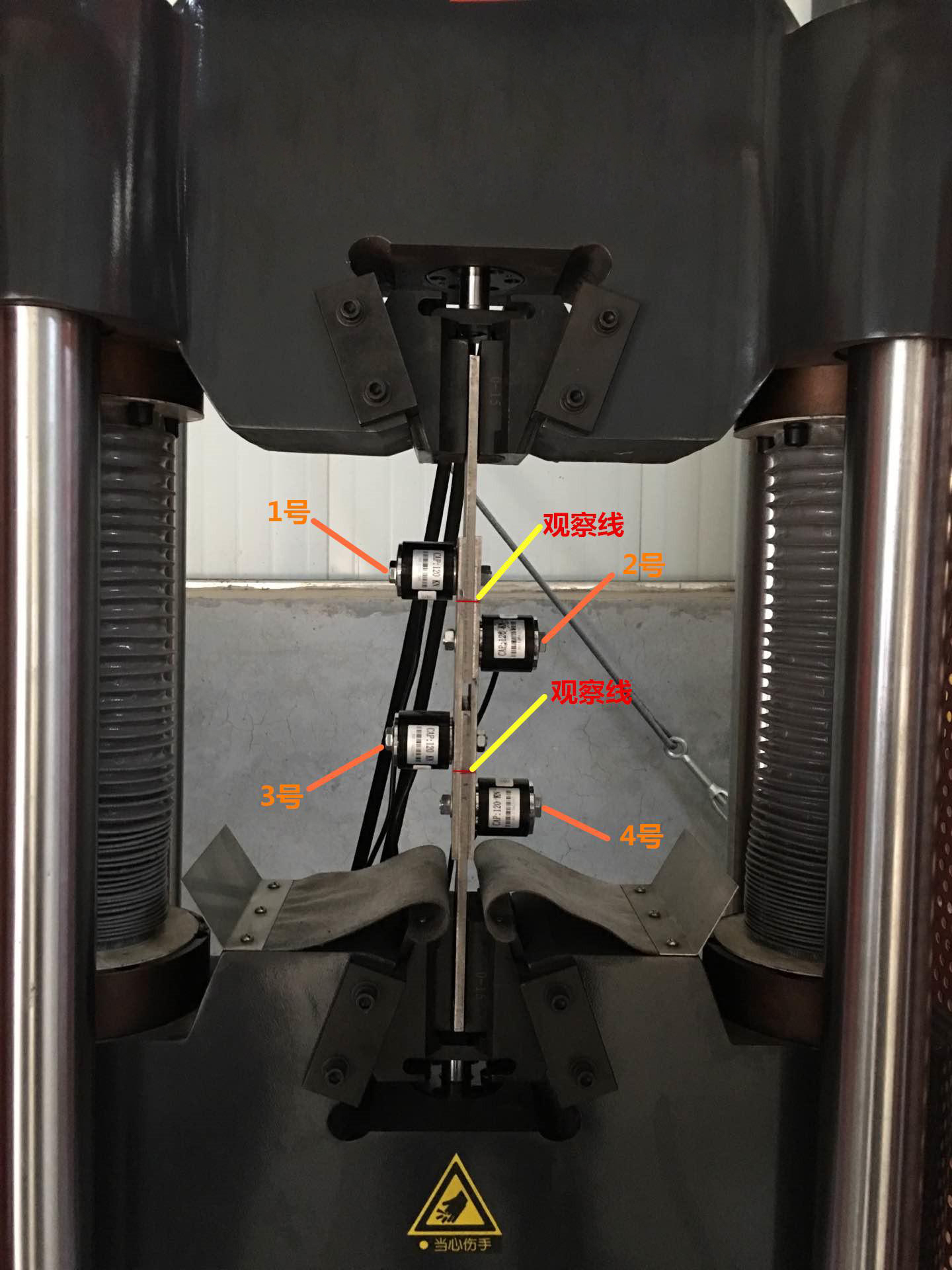

4. Product Physical and Test Illustrations

|

|

|

(Figure 5.1 LLG-24HY Overall View) (Figure 5.2 Test Example Illustration)

(Figure 5.3 Slip Plate Installation Position Schematic) (Figure 5.4 Slip Control Instrument)

5. Test Interface

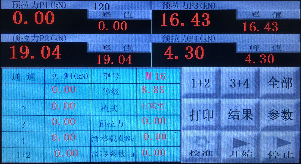

(Test Main Interface) (Test Status Interface)

6. User Preparation Conditions

-

- Requirements to clarify the test methods and standards referenced for execution as much as possible.

- Provide samples to complete the tests on this machine for product testing and factory inspection.

- Responsible for the receipt, storage, transportation, and placement of products.

- Contact the local metrology department for equipment measurement.

- Space and power supply required for equipment installation.

Related Products

Product inquiry

If you are interested in the product, please fill in the information and leave us a message, we will get in touch with you as soon as possible.

online message

Bottom link

Contact Us

Company Address:No.88, Ke Yun Road, Licheng District, Jinan City, Shandong Province

Sales Hotline: 008613204662621

Enterprise E-mail:dawn@tianchentest.com