Fastener Comprehensive Testing Machine NDW-20000/35000

Classification:

Key words:

Product Details

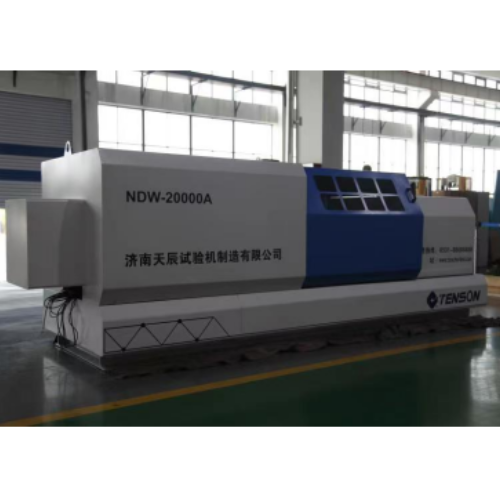

NDW-20000/35000 Comprehensive Testing Machine for Fasteners

- Introduction

NDW-20000 is a new type of comprehensive testing machine for fasteners designed by our company based on the standard GB/T16823.3 'Testing Methods for the Tightening of Threaded Fasteners' [ISO16047 Fasteners-Torque/clamp force testing]. It is mainly used for detecting the physical properties during the tightening process of large hexagon head bolts in steel structures, and can automatically calculate parameters such as the coefficient of friction between threads, bearing surface friction torque, tightening torque, clamp force, and torque coefficient. The system uses microcomputer control, providing high precision and sensitivity in controlling and measuring load and rotation angle, and displays test curves of torque/time, axial force (clamp force)/time, and torque/axial force (clamp force) in real-time.

The testing machine consists of the main unit, measurement control system, computer system and software package, functional accessories, and other components.

II. Technical Specifications

1. Maximum tightening torque: 20000 N·m;

2. Maximum clamp force: 2000kN (customizable according to customer requirements)

3. Maximum bearing surface torque: 15000 N·m;

4. Tightening torque measurement range: 200~20000N·m;

5. Clamp force measurement range: 20~2000kN;

6. Bearing surface torque measurement range: 150~15000N·m;

3. Relative error of test torque indication: 0.5 grade (±1%)

4. Torque repeatability of the testing machine: ≤0.5%

5. Torque resolution: 1/200000

6. Torsion angle measurement range: (0~1000)°

7. Test angle accuracy: ≤±0.1°

8. Relative error of torsion angle measurement: ±1.0%

9. Maximum torsion speed: 5r/min

10. Test bolt specifications: M30~M64

11. Test bolt length: 120~800mm(Note: Short length samples are only suitable for small diameter bolts, length ≥4d)

12. Power supply voltage: 380V ±10% 50HZ

13. Motor power: 18.5kw;

14. Main unit dimensions (reference): 3600×900×1200mm;

15. Main unit weight: approximately 2800kg

III. System Functions and Features

1. The main unit adopts a horizontal structure, making test operations convenient and performance stable;

2. The operation panel of the main unit is equipped with operation buttons, making it easy and quick to operate;

3. The motor is driven by a frequency conversion system. It has a wide speed adjustment range, uniform and stable loading, and accurate control;

4. The power part uses a planetary cycloidal pinwheel reducer to ensure uniform and stable loading and high rigidity of the system.

5. The moving part uses high-precision heavy-duty guide rails, facilitating the clamping of samples and fixtures.

6. The system uses dedicated microcomputer control software to display test curves of torque/time, axial force (clamp force)/time, and torque/axial force (clamp force) in real-time and can output test reports;

7. It has manual and automatic unloading functions;

IV. System Configuration

(1) Main Unit

1. Main unit frame 1 set

2. Motor + reducer 1 set

2. Frequency converter system 1 set

3. Photoelectric encoder 1 piece

4. High-precision torque sensor 1 set

5. Bearing surface torque measurement device 1 set

6. Clamp force measurement device (or multi-sensor combination) 1 set

7. Precision heavy-duty guide rail 1 set

8. Digital data acquisition and processing system (TENSON) 1 set

9. Computer control dedicated software (TENSON) 1 set

(2) Auxiliary Tools

1. Test fixture for large hexagon head bolts used in steel structures: M30, M33, M36, M39, M42, M45, M48, M52, M56, M60, M64 each 1 set, bolt length120~800mm(Note: Short length samples are only suitable for small diameter bolts, length ≥4d)

(3) Calibration Device (optional, not included as standard)

1. Torque sensor calibration device 1 set

2. Cantilever beam sensor calibration device 1 set

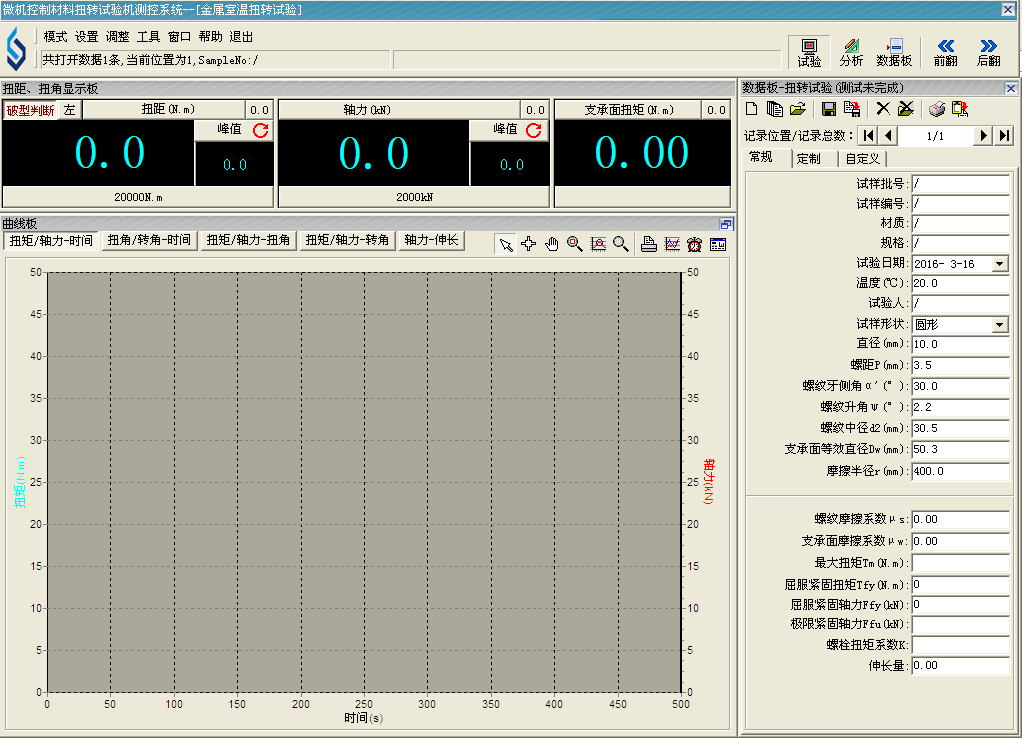

V. Software Functions and Features

① The control mode adopts an intelligent expert setting system, allowing users to compile the test process control method according to their actual requirements, automatically completing the test. It can set the axial load detection torque of the sample, and can also set the torque detection of the specimen for its axial load.

② The system uses a computer screen display with a fully Chinese interface and a human-computer dialogue mode. All operations of the experiment are completed by the computer, which displays the test torque, axial load, various test curves, and the working status of the testing machine on the screen. It also shows the calculated tightening characteristics of the bolts.

③ The computer collects data in real-time, processes the data, and provides functions for data storage, retrieval, statistics, and printing. It displays data in real-time, draws curves, and allows for curve magnification or reduction.

④ The size of the curve coordinates can be adjusted based on the actual test data.

⑤ The test report can be output in Word or Excel format.

- Multiple test curves can be overlaid for comparison and printed out.

- Digital zeroing and calibration can be performed.

- Test data is managed using a database system, making it easy to query and maintain.

Related Products

Product inquiry

If you are interested in the product, please fill in the information and leave us a message, we will get in touch with you as soon as possible.

online message

Bottom link

Contact Us

Company Address:No.88, Ke Yun Road, Licheng District, Jinan City, Shandong Province

Sales Hotline: 008613204662621

Enterprise E-mail:dawn@tianchentest.com