WDW-100 Microcomputer Controlled Steel Pipe Coupling Testing Machine

Classification:

Key words:

Product Details

1. Main Uses

This equipment is mainly used for the mechanical performance testing of steel pipe fittings, including anti-slip and anti-destructive tests for right-angle fittings and rotating fittings; rotational stiffness tests for right-angle fittings; tensile tests for butt fittings; compressive tests for bases; and strength tests for upper bowl fittings, welding strength tests for lower bowl fittings, strength tests for crossbar joints, welding strength tests for crossbar joints, and compressive strength tests for adjustable supports. This equipment is widely used in manufacturing enterprises of steel pipe fittings, quality inspection units, colleges and universities, research institutes, arbitration units, etc.

2. Applicable Standards

GB15831 'Testing Methods for Mechanical Performance of Steel Pipe Scaffolding Fittings', GB/T24911 'Testing Methods for Mechanical Performance of Bowl-type Steel Pipe Scaffolding Structures' and reference standards for disc scaffolding: JGJ231 'Safety Technical Specifications for Construction of Socket Disc Steel Pipe Scaffolding'.

3. Testing Parameters

|

Testing Parameters |

Fitting Type |

Parameter Requirements |

||||

|

GB15831 'Testing Methods for Mechanical Performance of Steel Pipe Scaffolding Fittings' |

||||||

|

Anti-slip Test |

Right-angle Fitting |

When P=7KN, Δ1 ≤7mm; When P=10KN, Δ2≤0.5mm |

||||

|

Rotating Fitting |

When P=7KN, Δ1 ≤7mm; When P=10KN, Δ2≤0.5mm |

|||||

|

Anti-destructive Test |

Right-angle Fitting |

When P=25KN, no part of the fitting should be damaged. |

||||

|

Rotating Fitting |

When P=17KN, no part of the fitting should be damaged. |

|||||

|

Torsional Stiffness Test |

Right-angle Fitting |

Torque of 900N•m, f≤70mm |

||||

|

Tensile Test |

Butt Fitting |

When P=4KN, Δ≤2mm |

||||

|

Compressive Test |

Base Fitting |

When P=50KN, no part of the fitting should be damaged. |

||||

|

GB/T24911-2010 'Testing Methods for Mechanical Performance of Bowl-type Steel Pipe Scaffolding Structures' |

||||||

|

Upper Bowl Fitting Tensile |

Bowl Fitting Tensile |

Test ForcePIncrease from 0KN to 15KN and then completely unload, then increase from 0KN to 30KN, maintaining this load for 2 minutes without damage to any part. |

||||

|

Lower Bowl Strength |

Bowl Welding Strength |

Test ForcePIncrease from 0KN to 30KN and then completely unload, then increase from 0KN to 60KN, maintaining this load for 2 minutes without damage to any part. |

||||

|

Crossbar Joint Strength |

Bowl Crossbar Strength |

Test ForcePIncrease from 0KN to 25KN and then completely unload, then increase from 0KN to 50KN, maintaining this load for 2 minutes without damage to any part. |

||||

|

Crossbar Joint Welding Strength |

Bowl Crossbar Joint Strength |

Test ForcePIncrease from 0KN to 10KN and then completely unload, then increase from 0KN to 25KN, maintaining this load for 2 minutes without damage to any part. |

||||

|

Main Technical Parameters |

||||||

|

1 |

Testing Machine Grade |

Grade 1 |

||||

|

2 |

Maximum Test Force |

100KN/2KN |

150KN/2KN |

|||

|

3 |

Force Measurement Range |

2%-100%FS |

||||

|

4 |

Accuracy |

Better than ±1% of the indicated value |

||||

|

5 |

Main Machine Range |

Four ranges: 1, 2, 5, 10, 2KN is not divided |

||||

|

6 |

Displacement Measurement Method |

Δ2 uses a dial gauge, other displacements use high-precision photoelectric encoders |

||||

|

7 |

Displacement Resolution |

0.01mm |

||||

|

8 |

Testing Speed |

0.05-500mm/min |

||||

|

9 |

Beam Movement Space |

900mm |

1100mm |

|||

|

10 |

Tensile Space |

700mm |

||||

|

11 |

Compression Space |

600mm |

||||

|

12 |

Main Machine Effective Width |

400mm |

||||

|

13 |

Overload Protection |

Dual protection with limit protection and software protection |

||||

|

14 |

Main Machine Power Supply |

1.5kW, AC220V±10%, 50Hz, single phase |

||||

|

15 |

Working environment |

Room temperature 10~35℃, humidity 20%~80% |

||||

IV. Equipment Introduction

1. Main machine: This machine adopts a double-space door structure, and the test space can be interchanged. The beam can be raised and lowered infinitely. The transmission part uses a circular arc synchronous toothed belt and a screw pair transmission, ensuring smooth transmission and low noise. The specially designed synchronous toothed belt reduction system and precision ball screw pair drive the movement of the test machine's moving beam, achieving gapless transmission.

2. Accessories:

One set each of interface tensile fixture, base compression fixture, right-angle fastener torsion bending stiffness accessory, and right-angle and rotating fastener anti-slip test fixture.

3. Electrical measurement and control system:

(1) Uses AC servo driver and AC servo motor, with stable and reliable performance, equipped with protection devices for overcurrent, overvoltage, overspeed, and overload.

(2) Has protection functions for overload, overcurrent, overvoltage, upper and lower displacement limits, and emergency stop.

(3) Built-in controller based on PCI technology, ensuring that the test machine can achieve closed-loop control of test force, specimen deformation, and beam displacement, enabling tests such as constant speed test force, constant speed displacement, constant speed strain, constant speed load cycling, and constant speed deformation cycling. Smooth switching between various control modes is possible.

(4) At the end of the test, it can manually or automatically return to the initial test position at high speed.

(5) Achieves true physical zeroing, gain adjustment, and automatic shifting, zeroing, calibration, and storage of test force measurement, with no analog adjustment links, and the control circuit is highly integrated.

(6) The electrical control circuit refers to international standards, complies with national electrical standards for testing machines, has strong anti-interference capability, ensuring the stability of the controller and the accuracy of experimental data.

(7) Has a network transmission interface for data transmission, storage, printing records, and network transmission printing, and can connect to the internal LAN or Internet.

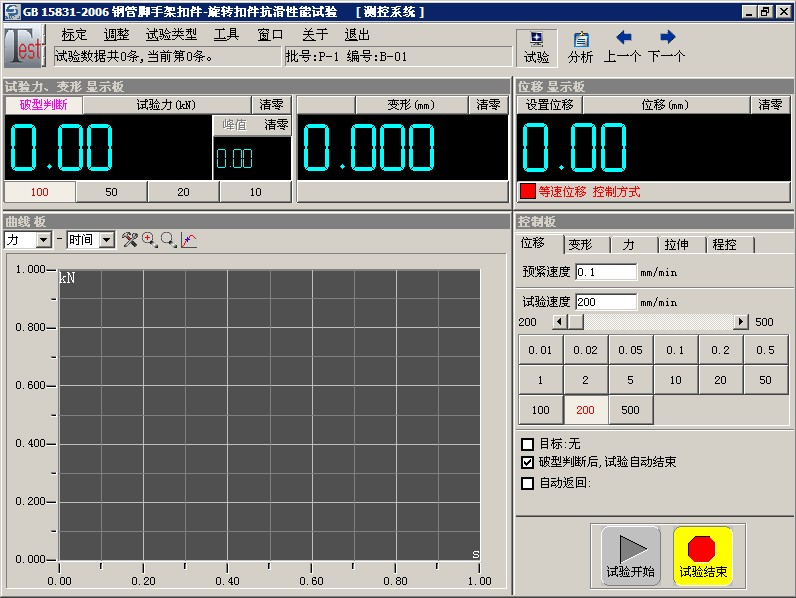

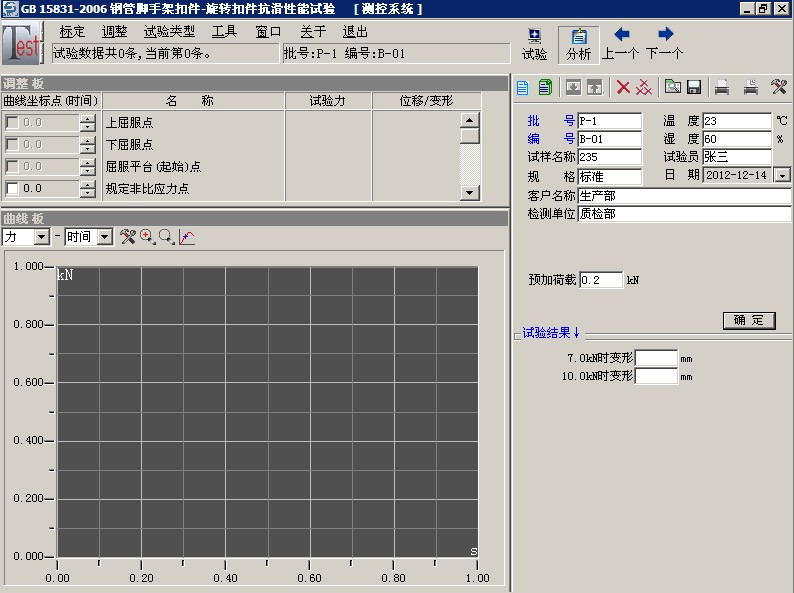

4. Main features of the software

This measurement and control software is used for various metal and non-metal tests on the testing machine, completing real-time measurement and display, real-time control, data processing, result output, and other functions according to the corresponding standards.

(1) Permission management is divided, with different levels of operators having different operation permissions, and the menus and other content that can be operated are also different, making it simple, convenient, and fast for ordinary operators while effectively protecting the system.

(2) Real-time measurement and display of test force and peak value, displacement, deformation, and other signals; achieves real-time acquisition and control under NT mode platforms such as Win2000, WinXP; and realizes precise timing and high-speed sampling.

(3) Real-time screen display of various test curves such as load-deformation and load-displacement, with the ability to switch observation at any time, and very convenient zooming in and out of curves.

(4) Has functions for computer storage, setting, and loading of test parameters, with zeroing, calibration, and other operations performed from the software, allowing for easy storage and retrieval of various parameters, making it convenient to switch when one main machine has multiple sensors, with no limit on the number.

(5) Supports various control methods, including open-loop constant speed displacement and constant speed force, and various closed-loop control methods; provides standard reference curves during the debugging of closed-loop parameters by advanced operators, allowing users to observe the impact of various parameters on closed-loop effects.

(6) Has an intelligent setting expert system for test process control modes, providing automatic program control programmers for professional users. Users can flexibly combine various control methods and speeds according to actual needs, compiling control programs suitable for their needs. The measurement and control software will automatically control the test process according to user settings.

(7) Uses human-computer interaction to analyze data. The processing methods meet widely applicable standard requirements, can automatically calculate various performance parameters such as elastic modulus, yield strength, specified non-proportional elongation strength, and can also allow manual intervention in the analysis process to improve accuracy; other data processing can also be performed according to user-provided standards.

(8) Test data is stored in text files for easy user query, and can be reprocessed using any common commercial reporting or word processing software, while also facilitating data transmission over the network.

(9) Can record and save the entire process data curve of the test, and has a demonstration function to reproduce the test curve. It can also perform curve overlay comparisons for easy comparative analysis.

(10) Can print test reports in formats required by users. Users can choose the basic information and test results and test curve content for report output, meeting various needs.

(11) Achieves digital zeroing and automatic calibration of test force and deformation, facilitating operation and improving machine reliability. Various parameter system settings are stored in file form for easy saving and recovery.

(12) Can be applied to various operating systems such as Win98, Win2000, WinXP. All operations such as test process control, beam movement speed changes, and parameter input can be completed using the keyboard and mouse, making it convenient and quick to use.

(13) Has an overload protection automatic shutdown function and can automatically determine sample fracture, automatically shutting down.

Depending on user requirements, the above software functions may be added, reduced, or adjusted.

5. Software and software operation interface:

(1) The software can run on Windows 98/2000/XP, with a user interface that presents a Chinese window system consistent with Windows style. All test operations can be completed on the computer screen using mouse input.

Test main interface

V. Main Configuration

|

Serial Number |

Project Name |

Manufacturer and Specifications |

Quantity |

Remarks |

|

1 |

Main machine frame |

Introduced Japanese technology |

1 unit |

|

|

2 |

AC servo motor and system |

|

1 set |

|

|

3 |

Deceleration system |

Timing belt |

1 set |

|

|

4 |

Ball screw pair |

|

2 sets |

|

|

5 |

Load sensor |

|

2 pieces |

100KN/2KN |

|

6 |

Computer |

Lenovo (current mainstream configuration) |

1 unit |

|

|

7 |

Printer |

HP color inkjet printer |

1 unit |

|

|

8 |

Photoelectric encoder |

|

1 unit |

|

|

9 |

Random tools, random documents |

User manual, installation manual, etc. |

1 set |

|

|

10 |

Fastener anti-slip performance fixture |

|

1 set |

|

|

Fastener torsional stiffness fixture |

|

1 set |

|

|

|

Fastener tensile performance tensile pin |

|

1 set |

|

|

|

Base compression fixture |

|

1 set |

|

Related Products

Product inquiry

If you are interested in the product, please fill in the information and leave us a message, we will get in touch with you as soon as possible.

online message

Bottom link

Contact Us

Company Address:No.88, Ke Yun Road, Licheng District, Jinan City, Shandong Province

Sales Hotline: 008613204662621

Enterprise E-mail:dawn@tianchentest.com