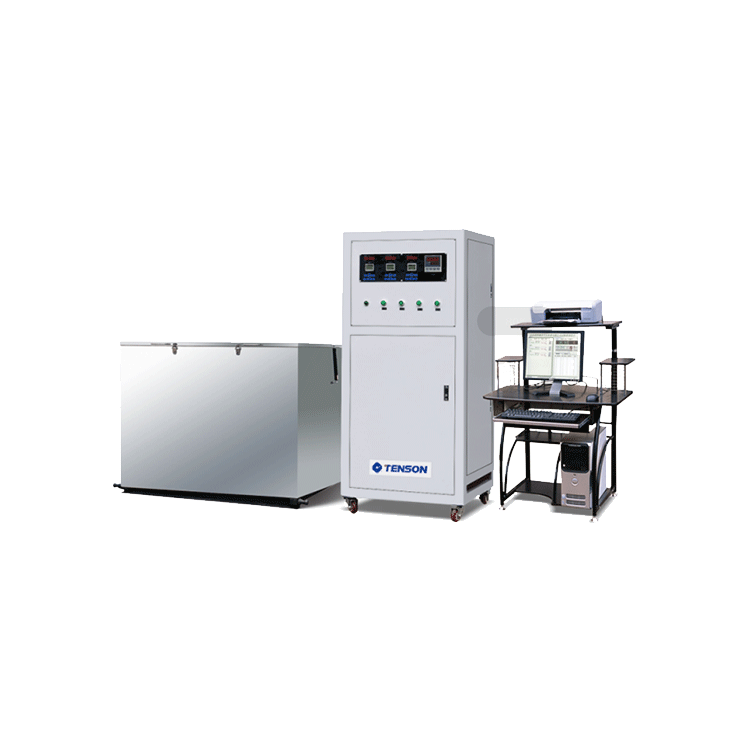

Pipe pressure testing machine XGY-10/16/20/25

Classification:

Key words:

Product Details

1. Main Purpose:

This machine is mainly used for determining the pressure resistance performance of various plastic pipes at a constant temperature. It is an essential testing device for plastic pipe manufacturers, colleges and universities, quality inspection units, and research institutions.

2. Implementation Standards:

1. GB/T 6111 'Determination of Internal Pressure Resistance Performance of Thermoplastic Plastic Pipeline Systems for Fluid Transport';

2. GB/T 15560 'Hydraulic Instantaneous Bursting and Pressure Testing Methods for Plastic Pipes for Fluid Transport';

3. GB/T10002.1 'Hard Polyvinyl Chloride (PVC-U) Pipes for Water Supply';

4. GB/T20221 'Hard Polyvinyl Chloride Pipes for Non-Pressure Buried Sewage and Drainage';

5. GB/T18742.1 'Polypropylene Pipeline Systems for Hot and Cold Water Part 1: General Principles'

6. GB/T18742.2 'Polypropylene Pipeline Systems for Hot and Cold Water Part 2: Pipes'

7. GB/T18742.3 'Polypropylene Pipeline Systems for Hot and Cold Water Part 3: Fittings'

3. Main Technical Indicators:

1. Maximum Pressure: 10MPa, 16MPa, 20MPa, 25MPa; (customization available for pressures above 25MPa);

2. Applicable Pipe Diameter: φ16-φ630mm

3. Test Pipeline: Conventional 3-way (can be expanded according to customer requirements);

4. Pressure Accuracy: ≤±1%;

5. Constant Pressure Range: 0.2 MPa~100%FS;

6. Constant Pressure Accuracy: -1%~+2%;

7. Timing Range: 1s~9999h;

8. Timing Accuracy: ≤±0.1%;

9. Power Supply Voltage: Three-phase, 380V±10%, 50Hz.

4. Basic Structure

This machine consists of a constant temperature water tank, clamping device, hydraulic system, computer, and electrical control system.

1. Constant Temperature Water Tank: Includes the constant temperature water tank body, heating tube, circulation pump, pressure relief hand valve, and sample vent valve, with the main function of keeping the tested pipe submerged in water at room temperature to 95℃.

2. Clamping Device: Ingeniously designed to effectively hold the sample securely and ensure reliable sealing;

3. Hydraulic System and Electrical Control System:

Its main function is to continuously and uniformly pressurize the tested pipes with water through hydraulic and electrical components such as a pressurizing pump, one-way valve, accumulator, high-pressure solenoid valve, and precision sensors, and then maintain pressure under automatic control by the computer and electrical system. During the pressurization or maintenance process, if one or more of the tested pipes leak, burst, or encounter other unexpected situations, the system can quickly shut off that branch, providing a safe protection function, and can automatically record the pressure value Pmax and time T at the moment of rupture. Other branches of the tested pipes can continue to maintain pressure until the specified time T is reached. The test can be conducted in automatic or manual mode, with automatic temperature control and real-time display of the constant temperature box's temperature.

5. Product Features:

1. Modular and standardized mainframe design: Each mainframe can support up to 6 test channels; the system supports up to 30 mainframes working simultaneously; users can add test channels as needed.

2. Computer remote centralized control: A set of measurement and control software can support hundreds of tests simultaneously.

3. Multiple water bath support: The system supports multiple water bath tests to improve the efficiency of water bath usage while reducing heating energy consumption.

4. Uses standard pressure sensors and standard secondary instruments for pressure collection: Improves pressure measurement accuracy and reliability, while facilitating user equipment verification.

5. Each channel uses two imported solenoid valves for control and is equipped with a water pressure buffer to ensure pressure control accuracy while isolating each test pipeline, ensuring independent operation of each test pipeline.

6. Two-stage buffer design for more stable test pressure.

7. Plunger-type high-pressure pump for pressure supply.

8. Water and electricity separation for high safety.

9. Automatically records test results and prints test reports in a custom format.

10. Reserved data interface for direct network connection to achieve resource sharing.

11. Measurement and control software with independent intellectual property rights, timely updates of testing standards, and acceptance of special customizations from customers.

6. Equipment Configuration:

|

Serial Number |

Configuration Name |

Specification Model |

Quantity |

Brand or Origin |

|

1 |

Mainframe Cabinet |

XGY-10/16/20/25 |

1 unit |

Jinan Tianchen |

|

2 |

Computer |

Qitian M428 |

1 unit |

Lenovo |

|

3 |

Printer |

HP |

1 unit |

Hewlett-Packard |

|

4 |

Computer Desk |

|

1 piece |

Jinan |

|

5 |

Plunger Pressure Supply System |

Assembly |

1 set |

Jinan Tianchen |

|

6 |

High-pressure water solenoid valve |

24V |

2 pieces/route |

GEVA Netherlands |

|

7 |

High-precision sensor |

0-16MPa, 0.25% |

1 piece/route |

Beijing Xingyi |

|

8 |

Water pressure buffer |

0.25L |

1 piece/route |

Ningbo |

|

9 |

Accumulator |

4L |

1 piece |

Ningbo |

|

10 |

Electric contact pressure gauge |

YX-60 |

1 piece |

Wuxi Huihua |

|

11 |

High-precision secondary instrument |

0.3 grade |

1 piece/route |

Xiamen Yudian |

|

12 |

Temperature control meter |

0.3 grade |

1 piece |

Xiamen Yudian |

|

13 |

High-pressure rubber hose |

With stainless steel joints |

1 set |

Jinan |

Optional products:

1. Standard stainless steel water bath: (Taking H110 water tank as an example, other specifications can be customized according to customer requirements)

1. H110 technical parameters:

1. Constant temperature range: Room temperature to 95℃;

2. Temperature accuracy: ±1℃;

3. Temperature uniformity: +3℃ to -1℃;

4. Maximum test tube diameter: φ110mm (three groups tested simultaneously)

5. Internal dimensions: Length: 600mm, Width: 400mm, Depth: 800mm (vertical)

2. H110 basic configuration:

Serial number Configuration name Specification model Quantity Brand or origin

1 Water tank Stainless steel 1 unit Jinan Tianchen

2 Electric heater 16KW 1 unit Jinan

3 Thermal circulation pump PH-041 1 unit Germany Wilo

4 Test piece hanging rack Stainless steel 1 set Jinan Tianchen

5 Compression refrigeration machine 1.5P 1 unit Jinan

2. Fixture:

1. Fixture type: Type A fixture

2. Standard specification range: φ16~φ110 (other specifications are accepted for customization), specific specifications are φ16, φ20, φ25, φ32, φ40, φ50, φ63, φ75, φ90, φ110, one set for each specification. The fixture includes a vent valve, conversion joint, installation screws, and sealing components.

3. Material: Stainless steel

Related Products

Product inquiry

If you are interested in the product, please fill in the information and leave us a message, we will get in touch with you as soon as possible.

online message

Bottom link

Contact Us

Company Address:No.88, Ke Yun Road, Licheng District, Jinan City, Shandong Province

Sales Hotline: 008613204662621

Enterprise E-mail:dawn@tianchentest.com