ndx series wire twisting testing machine

Classification:

Key words:

Product Details

Technical Overview

I. Instrument Purpose

1. The EZ series wire twisting testing machine is mainly used for: torsion testing of materials such as metal, non-metal wire, rods, and steel strands.

2. The EZ series wire twisting testing machine is widely used in: material manufacturing, quality supervision, metrology and quality inspection, commercial inspection industry, metallurgy, aerospace, medical devices, construction and building materials, and can also be used for teaching and research work in various engineering and technical universities.

II. Instrument Structure, Features, and Principles

1. Main body: consists of main machinery, Hall counter, microcontroller, digital display controller, protective cover (optional), etc.

2. Loading: motor loading, gearbox transmission.

3. Principle: control the motor's speed and number of rotations, and apply axial force to the workpiece by setting weights axially.

4. Features: easy to operate, compact structure, clear display, high accuracy, and other characteristics.

III. Standards

1. Standards for the manufacture and inspection of the instrument,

2. Standards and requirements that can be provided.

3. Standards and requirements that meet testing requirements.

IV. Instrument Overview

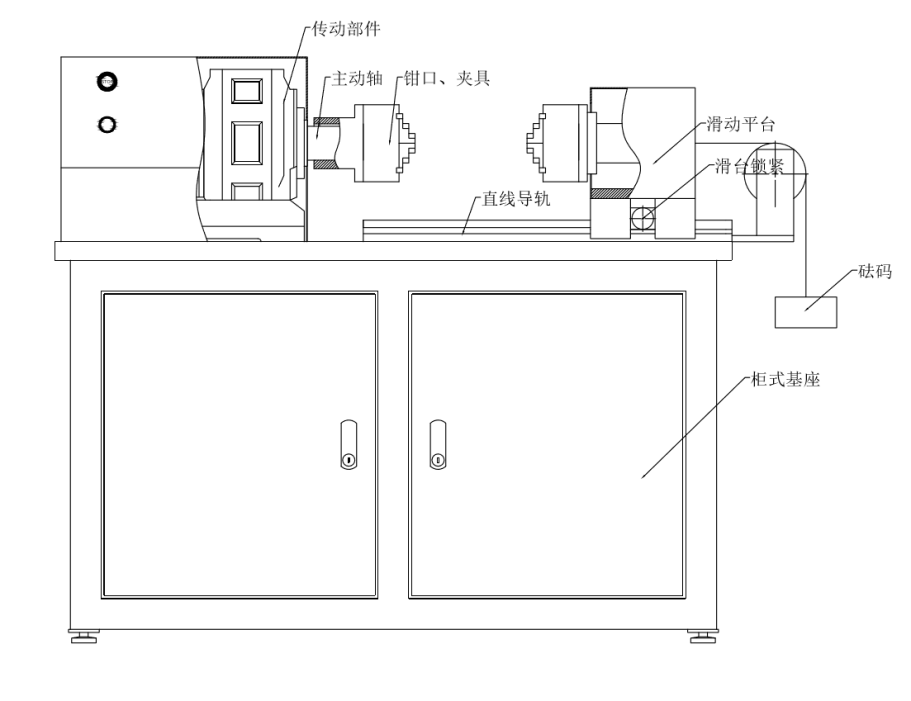

1. The EZ series wire twisting testing machine consists of the main unit, digital control system, functional accessories, and other components.

2. Schematic diagram of the main unit:

V. Software Overview:

V. Software Overview:

A. Functions

1. The main testing operations and control functions are integrated on the main control panel, making it convenient to operate and with clear display.

2. The display window includes: counting display window, frequency display window.

3. Manual and automatic modes, free operation.

VI. Main Parameters

1. Instrument model EZ-10

2. Clamping range 0.1-3.0mm, 3.0-7.0mm, 7-10mm

3. Effective space 100-300, 300-500.

4. Counting range 0-99999999

5. Speed range 15r/min, 30r/min, 60r/min manual setting.

6. Auxiliary tool type jaw

7. Lever ratio 1:10

8. Power supply voltage AC220V 50Hz

9. Product dimensions 1300×450×1200, unit: mm

VII. Main Configuration

1. Main unit frame 1 set

2. Gearbox 1 unit

3. Hall sensors 2 pieces

4. Motor, drive 1 set

5. Digital controller 1 unit

6. Auxiliary tools 2 sets

VIII. Accessories List

1. Power switch 1 piece

2. Emergency stop switch 1 piece

3. Linear guide rails 2 pieces

4. Linear bearings 4 pieces

5. Sheet metal shell 1 set

6. Weights optional

7. Wires several

8. Random tools according to packing list

IX. Installation and Debugging

Floor installation, remote training, on-site training (additional charges apply).

Related Products

Product inquiry

If you are interested in the product, please fill in the information and leave us a message, we will get in touch with you as soon as possible.

online message

Bottom link

Contact Us

Company Address:No.88, Ke Yun Road, Licheng District, Jinan City, Shandong Province

Sales Hotline: 008613204662621

Enterprise E-mail:dawn@tianchentest.com